Administrative Block

The backbone of our operations, the Administrative Block, handles planning, coordination, and efficient workflow management to ensure smooth production from start to finish. Ensures smooth coordination and timely execution from order processing to supply chain management.

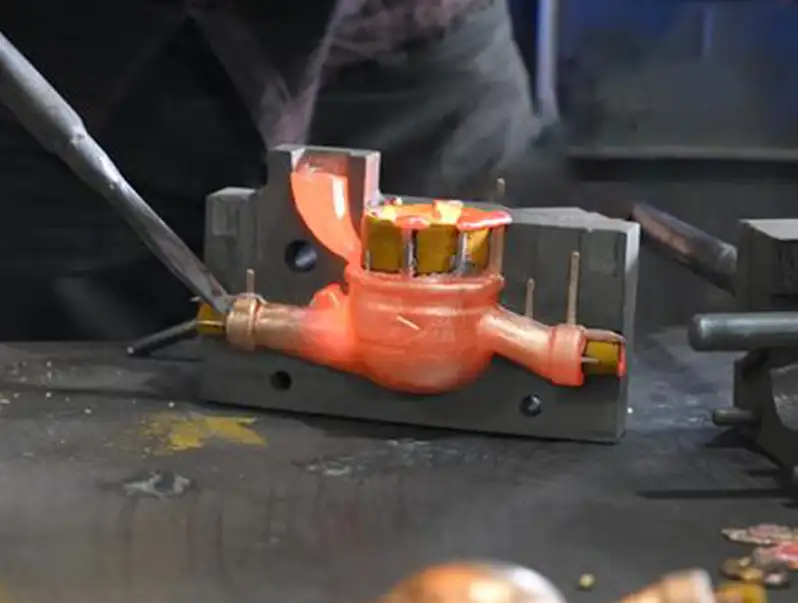

Foundry Area

Our Foundry Area is where raw metal is transformed into robust components through precision casting. It forms the base structure for our water meters, ensuring durability. High-temperature processes are carefully monitored for quality and safety.

Machine Room

Equipped with CNC and precision machinery, the Machine Room is where components are shaped to exact specifications. Here, engineering accuracy meets skilled craftsmanship, ensuring every part aligns perfectly with our performance standards.

Powder Coating Bay

In this bay, components receive protective powder coating to prevent rust and wear. The process not only enhances durability but also improves the aesthetic appeal of the meters, providing a uniform, high-quality finish.

Dial Printing

Dial Printing is where each meter face is marked with crisp, legible indicators. Using advanced printing methods, we ensure that the measurement units and numbering are clear, smudge-proof, and long-lasting for user-friendly reading.

Digit Wheel Printing

Precision printing is carried out on digital wheels using high-quality ink and printing techniques. This ensures clear, durable numbers that remain legible even after years of meter operation in varied environmental conditions.

Totaliser Assembly

The Totaliser Assembly section is where key components like digit wheels and gears are carefully assembled. This ensures accurate water usage tracking and smooth meter performance.

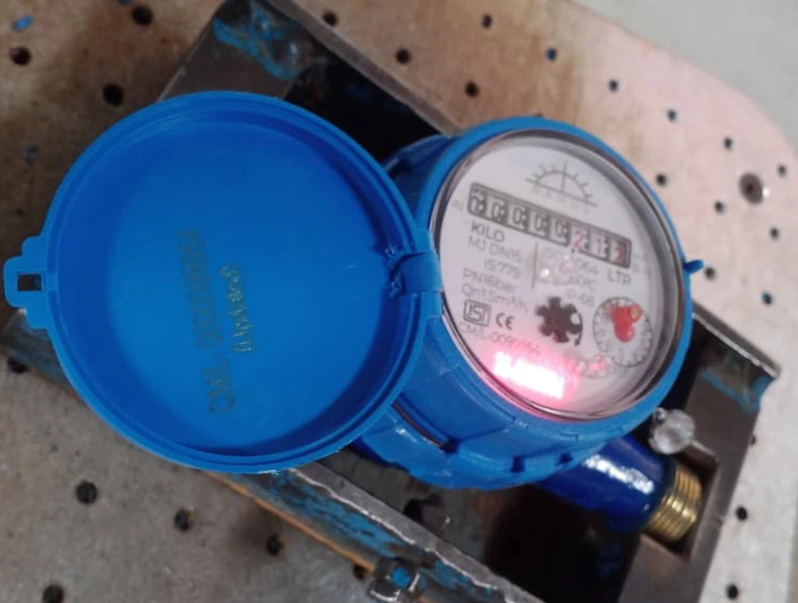

Quality Control

Our Quality Control department is where no compromise is made. Every component and final product undergoes strict inspection for defects, performance, and durability. Only meters that meet our benchmark standards move forward.

Pressure Testing Bay

To ensure the water meters can withstand high-pressure environments, they undergo rigorous testing in this bay. Each unit is checked for structural integrity, leak-proof performance, and safe operation under extreme conditions.

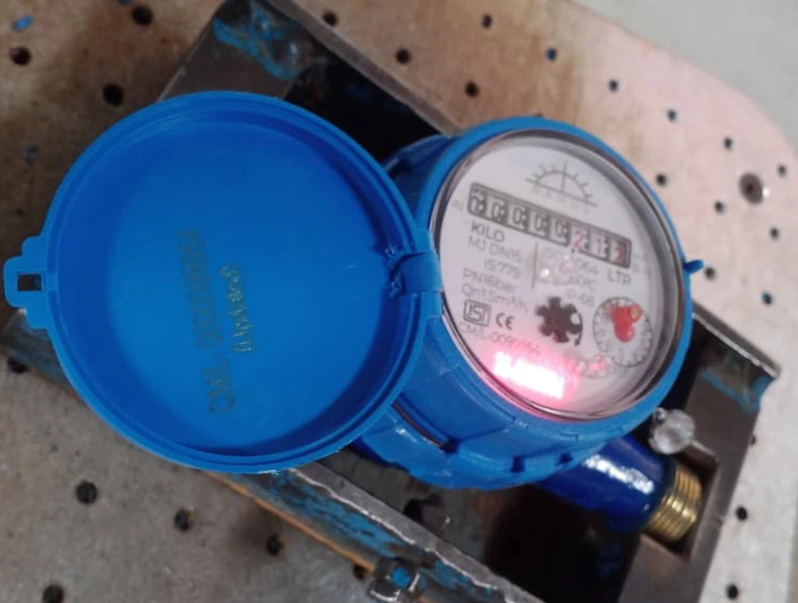

Testing Bay

Here, meters are tested for accuracy, calibration, and flow rate performance. This ensures that every water meter delivers consistent and precise readings before it reaches the customer.

Bulk Flow Meter Testing Bay

Large-capacity water meters are tested in this dedicated section. High-volume flow simulations are conducted to verify their reliability, pressure endurance, and long-term performance in industrial and commercial settings.

Laser Printing

Permanent markings such as serial numbers, QR codes, and branding are done using advanced laser technology. This step ensures tamper-proof identification and enhances traceability for after-sales service.

Packaging Bay

After final approval, each meter is carefully packed with accessories, manuals, and labels. The packaging process is designed to ensure safe transportation and easy installation upon delivery.

Store Room

Our Store Room houses raw materials and semi-finished goods in an organized layout. Efficient inventory management helps maintain smooth production flow and quick access to required components.

Finished Goods Godown

The final destination before dispatch, this area stores ready-to-ship water meters under safe and secure conditions. Proper labeling and stock management allow for efficient delivery to clients globally.

Plastic Injection Moulding Process

Using advanced moulding machines, this section produces precision plastic components used in water meters. The process ensures uniformity, high strength, and excellent resistance to wear and tear.

R&D Department

Our Research & Development team drives innovation by improving existing designs and developing new technologies. Focused on accuracy, sustainability, and customer needs, the R&D department is the foundation of future-ready meters.